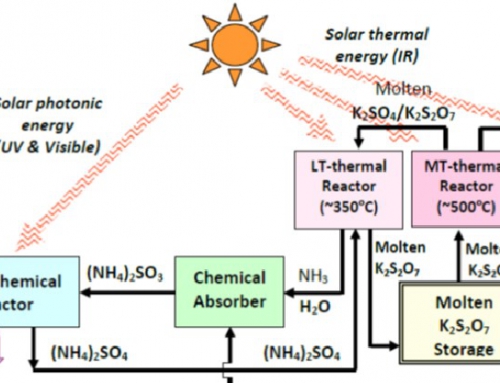

Experimental and numerical investigation of the aperture size effect on the efficient solar energy harvesting for solar thermochemical applications

Sarwar J., Georgakis G., Kouloulias K. and Kakosimos K.E., “Experimental and numerical investigation of aperture size effect on the efficient solar energy harvesting for solar thermochemical applications”, Energy Conversion and Management 92:331-341 (2015). doi: doi:10.1016/j.enconman.2014.12.065

https://goo.gl/fg3qHG

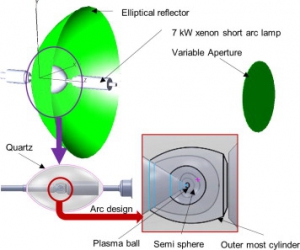

In this paper, experimental and numerical work have been undertaken to investigate the steady state temperatures throughout the day of a cylindrical solar receiver when using fixed and variable size apertures. A high flux solar simulator, consisting of a 7 kW xenon short arc lamp, is employed as a light source. The sunlight intensity variations at early morning (06:30), morning (07:15) and noon (12:00) time of a reference day are imitated by changing the input current to the lamp. Experiments have been performed with different aperture diameters across selected irradiance levels to imitate sunlight variations. An optical model is developed to simulate incident flux distribution and the output is compared with the experimental measurements for validation. A finite volume algorithm is developed, based on a coupled Monte Carlo heat transfer model, to calculate the steady state temperatures in the receiver. Experimental and numerical temperatures are compared and an excellent agreement with an average temperature difference of ± 0.2%, is observed. The optimum aperture size varies with the change in irradiance intensity and therefore the time of day. Simulations for a 30 kW light source show that the daily steady state temperature differential for fixed apertures of 8 cm -10 cm is 170 K – 190 K. Variable apertures reduce power consumption by half when compared to fixed apertures. Variable apertures maintain steady state temperatures of 1000 K, 1100 K and 1200 K by consuming 26.8 kWday, 33.2 kWday and 26.9 kWday, respectively.